Farafan Toos Mold and Part Manufacturing Company

Farafan Toos began its journey in 1995 by producing various types of industrial molds, including plastic, metal, and die-cast molds. Through the design and manufacturing of complex molds and parts, it quickly gained recognition among industry leaders. In 2021, the company proudly achieved the prestigious status of a knowledge-based enterprise.

We are proud to have earned the trust of over 500 clients through 30 years of expertise in mold making and industrial manufacturing.

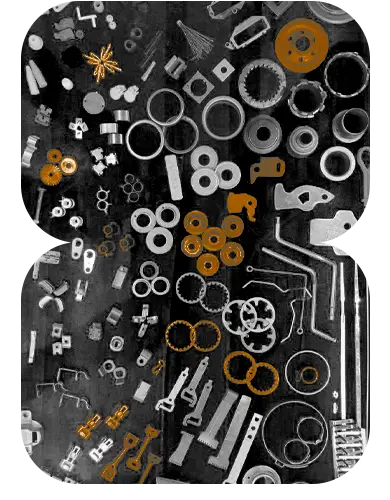

With over three decades of experience, Farafan Toos specializes in the design and production of a wide range of industrial molds — plastic, metal, die-cast, and progressive — as well as the manufacturing of metal parts through pressing and die-casting methods. We deliver precise, engineered solutions that meet the latest industry standards.

With over three decades of experience, Farafan Toos specializes in the design and production of a wide range of industrial molds — plastic, metal, die-cast, and progressive — as well as the manufacturing of metal parts through pressing and die-casting methods. We deliver precise, engineered solutions that meet the latest industry standards.

Specializing in the engineering analysis and precise construction of metal, polymer, and die-cast molds to serve a broad range of industries.

At Farafan Toos, we combine technical expertise, hands-on experience, and advanced engineering software to design and manufacture a wide range of high-quality industrial molds tailored to specific industry needs.

Producing complex plastic injection molds with pre-production analysis and delivering high-standard, reliable molds for diverse industrial applications.

Trusted by Industry Leaders

Name

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Egestas purus viverra accumsan in nisl nisi.

We operate in the design and manufacturing of high-quality industrial molds using advanced technologies and precise machinery.

Farafan Toos started its operations in 1995 and quickly gained recognition through its production of complex molds and parts, ultimately achieving knowledge-based enterprise status in 2021.

Frequently Asked Questions

We handle every step of the process, from the initial design phase to final mold production, with high precision and quality. The process includes client consultation, CAD/CAM design, mold manufacturing using advanced CNC machines, and final mold testing and optimization. All stages are carried out under the supervision of our expert engineers.

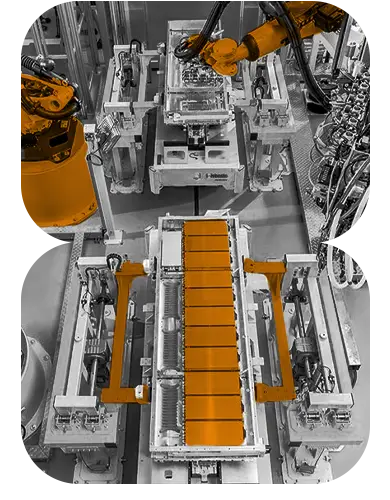

Our company is capable of producing a wide range of industrial parts for various sectors, including automotive, electronics, medical, and home appliances. We also offer customized production services to meet specific client requirements.

For detailed information on prototype production, please contact our experts. You can find our contact information in the "Contact Us" section of the website.

We use high-quality raw materials and advanced equipment to manufacture our molds and parts. Additionally, a strict quality control process is implemented at every production stage to ensure all products meet industrial standards.

Farafan Toos: Engineering Excellence in Mold and Part Manufacturing

With years of experience in design, production, and engineering services, Farafan Toos is recognized as one of the industry’s leading companies. Our mission is to provide precise, high-quality solutions to various sectors including automotive, electronics, home appliances, medical equipment, and heavy industries.

Our Services

Industrial Mold Design

Our engineering team designs high-precision molds tailored to client requirements, using advanced CAD and CAM software.Mold Manufacturing

We manufacture industrial molds with the highest standards of quality and durability using modern machinery and cutting-edge technology.Industrial Part Production

Producing precise components for various industries with high-grade materials and advanced production lines.Engineering and Consulting Services

Offering consulting for design optimization and industrial component enhancement to reduce costs and boost efficiency.

Our Areas of Expertise

Mold and part manufacturing forms the backbone of many industries. In the world of production, it’s not just about shaping materials — it’s about shaping innovation.

What is Mold Manufacturing?

Mold manufacturing is a production process where a liquid material is poured into a cavity-shaped mold and then solidified. The finished casting is removed from the mold, ready for use.

This versatile process merges technical precision with creative craftsmanship, bridging the gap between art and industry.

Molds play a vital role in manufacturing nearly every product around us, giving shape to countless objects that define our daily lives.

Our Types of Molds

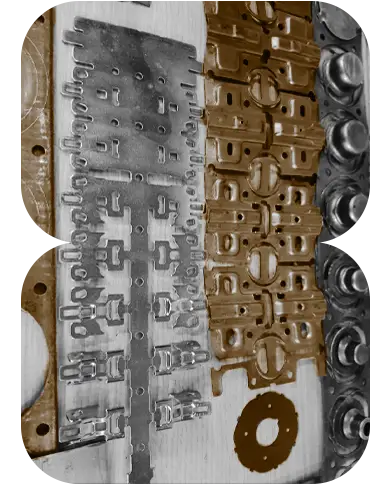

Metal Molds

We specialize in designing and manufacturing durable, high-precision metal molds for sectors like automotive and home appliances. Using premium materials and advanced technologies, we deliver molds designed for mass production and extended service life.Die-Cast Molds

Our die-cast molds are engineered for high-pressure casting processes, producing metal components with intricate details and smooth surfaces — ideal for automotive and industrial applications. Precision and consistency are key in our die-casting solutions.Polymer Molds

We excel in manufacturing polymer molds for plastic injection molding applications across packaging, electronics, and home appliance industries. Advanced equipment and strict quality standards ensure our polymer molds meet diverse production needs.

What is Part Manufacturing?

Part manufacturing is a critical segment of the production chain, directly impacting the quality and performance of end products. At Farafan Toos, we combine engineering expertise, advanced machinery, and premium materials to produce high-precision, durable parts for a wide range of industries, driving efficiency and enhancing product quality.

Our Part Manufacturing Services

Industrial Part Design and Modeling

We create detailed designs and 3D models using advanced CAD software to ensure dimensional accuracy and functionality before production.Metal and Non-Metal Part Production

Our production capabilities cover a wide range of materials, including metal, polymer, and composite parts, manufactured with precision CNC machines and state-of-the-art equipment.Machining and Finishing

Precision machining and surface finishing processes ensure the final parts meet exact dimensional and aesthetic specifications.Mass and Custom Production

We offer both large-scale production and customized manufacturing services to meet unique customer requirements.Quality Control

All parts undergo rigorous quality control, including dimensional checks, strength tests, and durability assessments, ensuring they meet the highest industry standards.

If you are looking for a reliable partner to supply high-quality industrial parts, Farafan Toos is ready to collaborate with you.